| English. | Japanese. |

|

|

Yesterday's access. |

| Introduction. | [Lily Diary.】 A diary of life in Mindanao. |

| 25/11/20 | Satellite tracking Sat Track - Development Version |

| 25/11/19 | Kenpro KR-400 arrived by EMS |

| 25/11/18 | 3.5MHz Antenna Toroidal Core |

| 25/11/16 | WiMO V/UHF Cross Yagi |

| 25/11/16 | WSJT-X Automatic operation Ver0.1.1 |

| 25/11/09 | Eyeball with DU9JJY in Cotabato |

| 25/11/04 | TNC software for APRSVer1.2 |

| 25/11/03 | Indonesian satellite IO-86 event |

| 25/10/29 | Active Satellite List  |

| 25/10/24 | FTDX3000 repair completed |

| 25/10/17 | Kenpro KR-500 Repair Completed |

| 25/10/15 | ARISS SSTV DIPLOMA |

| 25/10/14 | International Space Station Information |

| 25/10/13 | ST2 interface for driving AC motor rotors |

| 25/10/12 | Received APRS signals from ISS |

| 25/10/11 | TNC software for APRS manual |

| 25/10/10 | TNC software for APRSVer1.0 |

| 25/10/09 | Making myopia glasses |

| 25/10/09 | ICOM IC-820H PLL UNLOCK repair |

| 25/10/05 | 435MHz Cross Yagi antenna production preparation |

| 25/10/04 | Receiving SSTV from the International Space Station |

| 25/10/03 | Repair of elevation rotator KR-500 |

| 25/10/02 | 145MHz Cross Yagi antenna production preparation |

| 25/10/01 | received APRS signal from ISS |

| 25/09/29 | CQ WW RTTY contest |

| 25/09/27 | SSTV from the ISS |

| 25/09/26 | WARC band fan-out antenna |

| 25/09/25 | levation rotator KR-500 acquired |

| 25/09/23 | APRS TNC software Dire Wolf with Hamlib |

| 25/09/23 | TNC software direwolf |

| 25/09/21 | Russian satellite RS-44 beacon |

| 25/09/20 | Installing a radio in a car |

| 25/09/17 | DH1NGP Peter radio vehicle |

| 25/09/13 | 3.5MHz SWR increased |

| 25/09/12 | 3.5MHz Zepp antenna adjustment |

| 25/09/10 | Geostationary satellite QO-100 |

| 25/09/09 | Preparing for the satellite station |

| 25/09/08 | DU9JJY satellite station |

| 25/09/07 | 14MHz late at night |

| 25/09/03 | Mitsubishi Strada Pickup Truck Oil Change |

| 25/08/18 | WSJT-X Automatic operation Ver0.1.0 |

| 25/08/18 | JTDX Autonomous operation Program Ver0.6.3 |

| 25/08/10 | Software List |

| 25/07/26 | AutoCWType_Ver1.5.8 |

| 25/07/20 | Create one month's worth of ADIF files from JTDX Ver 2.6.5 |

| 25/07/19 | Japan's Radio Wave Usage Tax |

| 25/07/13 | IARU HF Contest |

| 25/07/10 | Software updates |

| 25/07/08 | DXV500ZS linear amplifier repair |

| 25/07/07 | CQ Machine Program |

| 25/06/21 | LoTW system upgrade |

| 25/06/18 | RG8 for 3.5MHz arrived |

| 25/06/15 | Time setting Ver0.5 |

| 25/06/14 | Drone Habsan ZINO arrives |

| 25/06/12 | Philippine Independence Day |

| 25/06/11 | Algeria 7X2RF QSL card. |

| 25/06/10 | Translation API Program |

| 25/06/09 | DXCC150 award certificate arrived |

| 25/06/08 | AutoCWType_Ver1.4.1 |

| 25/06/07 | Introducing the Shack |

| 25/06/06 | A portrait drawn by ChatGPT. |

| 25/05/26 | Windows full-width/half-width switching. |

| 25/05/17 | OK2ZAW BCD to 16 converter. |

| 25/05/16 | For 3.5MHz Zepp antenna. Stepping motors |

| 25/05/15 | 3.5MHz stepping motor design. |

| 25/05/14 | 3.5MHz tuning coil installed. |

| 25/05/11 | 3.5MHz antenna installation completed. |

| 25/05/03 | JTDX Autonomous Driving Program Ver0.4.3. |

| 25/04/26 | Drone Habsan ZINO. |

| 25/04/25 | Time setting Ver0.3. |

| 25/04/24 | AutoCWType_Ver1.3. |

| 25/04/23 | Preparing for FTDX3000 LCD repair. |

| 25/04/22 | Installation plan for 3.5MHz Zepp antenna. |

| 25/04/21 | AutoCWType_Ver1.1. |

| 25/04/20 | 10,14MHz antenna installation completed. |

| 25/04/19 | JTDX Autonomous Driving Program Ver0.4.1. |

| 25/04/19 | 14MHz antenna pole installed. |

| 25/04/18 | ThinkPad X390 repair completed. |

| 25/04/17 | Search is now possible. |

| 25/04/15 | Preparing the 10MHz dipole. |

| 25/04/12 | Hexbeam Part8. |

| 25/04/06 | My ThinkPad X390 is broken. |

| 25/04/05. | Time setting program. |

| 25/03/31 | JTDX Autonomous Driving Program. |

| 25/03/30 | Automatic log sending from CWType to Hamlog. |

| 25/03/21 | Hexbeam Part 7. |

| 25/03/20 | FreeDV Part 3 First QSO. |

| 25/03/18 | FreeDV Part 2 QSO in the shack. |

| 25/03/16 | Hexbeam Part 6. |

| 25/03/15 | Install FreeDV Part1. |

| 25/03/09 | Hexbeam Part5. |

| 25/03/07 | Hexbeam Part 4. |

| 25/03/05 | 28MHz antenna modification |

| 25/03/01 | FTDX3000 is broken! |

| 25/02/28 | Pileup at 50MHz FT8. |

| 25/02/28 | DXV500ZS linear amplifier repair. |

| 25/02/27 | Tower pipe rebuilding plan. |

| 25/02/26 | Direction to Japan from Ozamiz. |

| 25/02/26 | 28MHz is not available. |

| 25/02/23 | DXV500ZS linear amplifier repair. |

| 25/02/22 | Hexbeam Part 3 |

| 25/02/21 | Hexbeam Part 2 |

| 25/02/18 | 28MHz antenna construction. |

| 25/02/17 | 18,24MHz antenna height construction. |

| 25/02/16 | Z26NS Cosovo. |

| 25/02/14 | 21MHz FT8 |

| 25/02/12 | 7,21MHz antenna repair. |

| 25/02/08 | Operating CW at 21MHz. |

| 25/02/05 | DXV500ZS linear amplifier failure. |

| 25/01/19 | Input Director. |

| 25/01/14 | Temporary license renewal. |

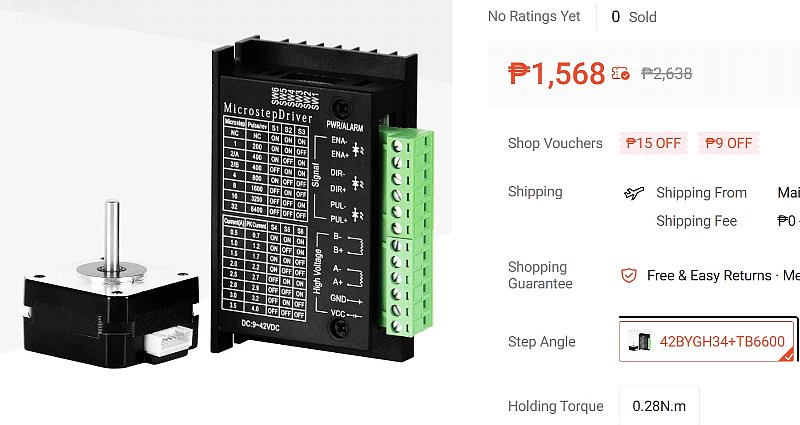

| 3.5MHz antenna, stepping motor this and that (2025/05/16) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| On the use of a stepping motor for remote tuning of a tuning barycon for a 3.5 MHz Twep antenna I looked up a few things on ChatGPT. I did get some information from ChatGPT about the step IR antenna, Other information about stepping motors was almost the same as yesterday's information from JG2TST Matsui. |

||||||||||||||||||||

| I asked ChatGPT about the step IR yagi antenna. The following is a description of the stepper motor drive system used in SteppIR antennas (e.g., SteppIR 3-elec., BigIR, etc.) and its relationship to the controller: Overview of Stepping Motor Drive of SteppIR Antenna Driving system: SteppIR typically uses bipolar stepping motors, driven by

Put the controller near the motor? →.NO In the SteppIR stock, the motor controller is located in the shack and is extended to the motor by power lines (A+/A-/B+/B-). It is not controlled by step, direction, or enable (PUL/DIR/EN) signal wires. |

||||||||||||||||||||

|

Is the EN/DIR/PUL system (STEP/DIR control) stable? This is a common CNC control method and is often used in motor control ICs (e.g., TMC, A4988, DM556, etc.). Conditions for stabilization with this method:

|

||||||||||||||||||||

|

||||||||||||||||||||

|

||||||||||||||||||||

| If using ZK-SMC01 and TB6600, it is much more stable to pull 30m of EN/DIR/PUL signal line than to pull 30m of A+, A-, B+, B- motor line. | ||||||||||||||||||||

|

||||||||||||||||||||

Recommended configuration

|

||||||||||||||||||||